-

Industrial Dual-Coil Metal Detection Sensor (VLF)

This device is used for installation on conveyors to prevent the passage of ferrous and non-ferrous metals. These sensors are widely used in cement, gypsum, sand, flour making, machine bricks, rubber and plastic, wood and paper industries, chipboard and MDF, other industries and mines. And prevents damage to mills, qubits, crushers, extruders, waltzes, cylinders, types of pressing systems, chipper, etc. This sensor has two separate transmitter and receiver coils as well as separate electronic panels that are connected to each other by coaxial cables. The coil of this device is installed in two pieces on the conveyor and the coils are screwed on both sides to prevent the conveyor from re-operating. The metal detection system of this sensor is VLF, which includes the following major advantages

- Stabilizer power supply - Accurate and error-free detection of ferrous and non-ferrous metals - No malfunction of the device due to changes in temperature, humidity, magnetic effects of the earth and... - Automatic and continuous testing and adjustment of the device after initial settings - No need for daily, weekly or even monthly controls and settings - Easy installation of the device with the help of manual and no need for a company expert -

Pure metal detection sensor with PI system (Pulse Inductive)

The sensor has a non-metallic body, which is the advantage of this system to pass impure metals and iron ore, including magnetite and hematite, which is an integral part of the canoire or part of the raw material and is the detection of damaging metals in the factory production line.

The sensor is widely used in cement factories, some mines, iron ore concentrate, pellets or even iron and steel smelting factories.

In the PI system or pulse induction, the pulses provided by the circuit oscillator with a special frequency and diotics are induced to the transmitter's coil after the reinforcement process. The range of this induction is 2000 volts, which will be turned off until the next cycle.

If the iron metal damping passes through the coil diaphragm due to the formation of the Eddy current, the moderation time will be different and the metal detector uses the sampling -integral circuit and the multi -step reinforcement of the metal and issued the output steering wheel. -

Metal Diagnosis Sensor for Textile Industries

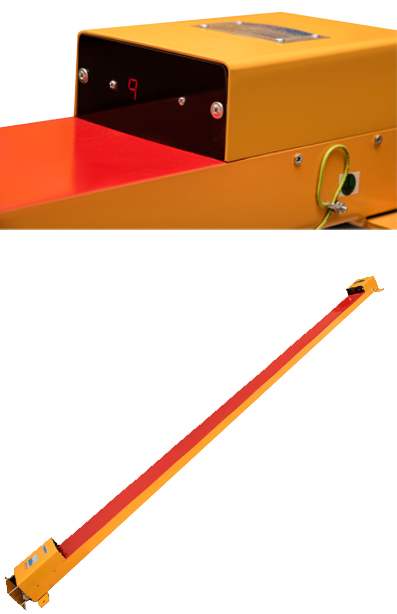

The sensor is mainly used to protect the spiral blade in the completed factories (Shirring, Carding) towels, blankets, carpets and fabrics. This machine is made with a metal body longitudinally and a coil of 15 cm wide and 6 cm high and on different lengths depending on the length of the blade and the width of the product. This sensor with the VLF system is capable of detecting all kinds of iron and non -iron metals in the towel and carpet texture, etc. to protect the blade The advantage of this device is the lack of a separate power panel and the installation of electronic boards on both sides of the device to facilitate the installation and lack of noise due to the vibration of wires and cables.

Other benefits of this device include:

- Use a filter line to prevent feeding line noise - Show detection size by 7 LEDs - Show sensitivity from 0 to 9 by segments - Ability to convert the command relay mode from NC to NO or from automatic to manual mode - Easy to install the device with the help of a manual without the need for a company expert